光学透镜已经广泛应用于消费电子、监控、医疗、半导体、激光、检测、测量、科研、军工等行业。作为对品质的初步筛选,ISO认证可以作为一个工厂对品质把控的参考依据,这是专业的对生产制造企业流程可行性的一个认证。尤其是一些对资质要求较高的行业,像军工和医疗仪器项目,这是最基本的因素。这也为我们对供应商的筛选提供了一种思路和方向,至少在理论上整个工厂的管控符合品质管控的要求。

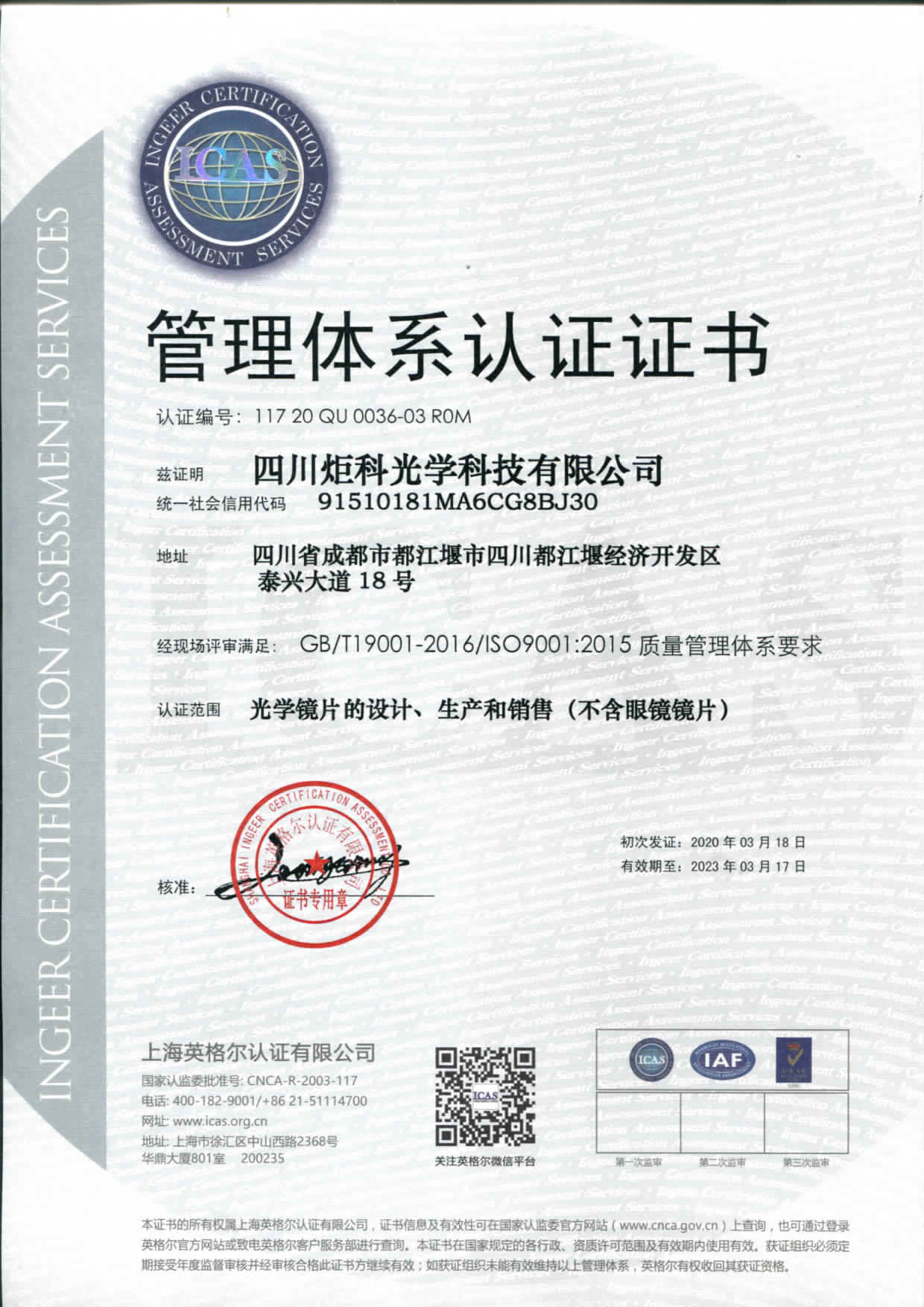

作为一家高精度光学元器件的加工制造企业,成都炬科光学在很早以前就取得了ISO9001质量体系认证。为了更加有效的整合和提升产品的品质和产能,成都炬科光学投资新建的园区于19年年中顺利完工,并在19年10月初进行整体搬迁和扩产。经过评测机构的考察和实际验收,四川炬科光学新工厂已经取得专业机构颁发的ISO9001:2015认证证书。

当然,作为定位于高精密光学透镜、镜头、光学元器件生产企业,在ISO的质量管控体系之下,还有许多结合自身产品和工艺的细节需要灵活运用。炬科光学的光学透镜、镜片加工,怎么样能够保证其产品的稳定性和可靠性。经验丰富的技术工人、精密匹配的加工设备的基础之上,关键还需要能够准确量化的专业检测仪器。目前对于光学元件的几个关键核心指标,炬科光学分别配置了用于检测曲率半径的ZYGO干涉仪和VEECO干涉仪以及球径仪、用于检测面形的ZYGO激光干涉仪、用于偏心检测透射式和反射式中心仪、用于透过率反射率检测的岛津光谱仪等专业的可量化的检测仪器。三者结合让炬科光学加工的光学透镜具有高稳定性和高一致性的特点。